The nanodac recording functionality utilises the secure strategies and UHH format developed by Eurotherm through years of recording expertise. The unit also provides user wiring from the front of the product for detailed configuration without the need to connect to a PC. Views include: Horizontal and vertical trends Horizontal and vertical bar graphs Numeric Alarm status, and control loops. The 3.5” TFT display offers incredibly clear visualisation of process parameters with a wide selection of configurable views to best suit the application. This secure data recording device with accurate control is enhanced by a full colour, ¼ VGA display to bring a crystal clear operator interface to even the smallest of machines. The compact ¼ DIN panel mount unit offers four high accuracy universal inputs for data recording and PID control. The nanodac™ recorder/controller offers the ultimate in graphical recording combined with PID control for a box of its size. ** When any application block is selected, 2 Control Loops must also be selected ** 15 Virtual channels come standard, additional Virtual channels 16-30 are available as an option ONLY when either Modbus Master or Ethernet/IP options are selected.

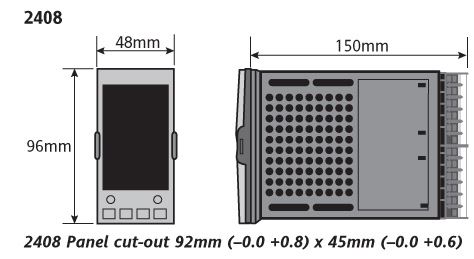

With industry-standard protocols including: Modbus, DeviceNet®, Profibus DP, and Eurotherm® Bisync.***Please note that the model number is made up as follows:*** Nanodac/SupplyVoltage/Controller/Programmer/Output1-3/ApplicationBlocks/ Communications/Bezel/ ToolkitBlocks/ENG/OEMSecurityOption/xxxxx/xxxxx/ xx/BatchOption/AuditorOption/xx/xx/xx Important Notes: Digital communicationsĪvailable with either EIA485 2-wire, 4 wire or EIA232. Alarms can be full scale high or low, deviation from setpoint, rate of change or load failure alarms. Up to four process alarms can be combined onto a single output. In addition an adaptive tuner will handle processes with continually changing characteristics. A one-shot tuner is provider to set up the initial PID values and to calculate the overshoot inhibition parameters. Precise controlĪn advanced PID control algorithm gives stable 'Straight-line' control of the process. The controllers accept a range of plug-in modules, heating, cooling, or process outputs, analog retransmission, second process value input and remote setpoint. Either PID, ON/OFF or Motorized valve control can be configured, satisfying both electrical and gas heating applications amongst others.Ī setpoint programmer with up to 20 programs of 16 segments is available. The 2408 1/8 DIN unit is a high stability controller with an extensive range of options.

Setpoint programmer providing up to 16 segments Versatile, high stability temperature or process controllers

0 kommentar(er)

0 kommentar(er)